7406 – SIGMACOVER 211

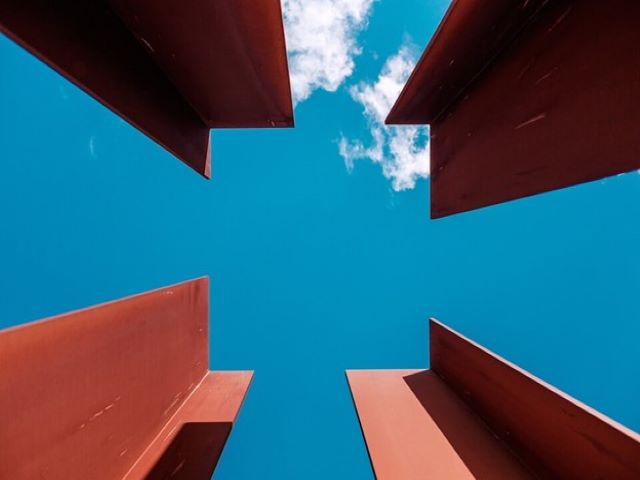

Two component polyamide cured epoxy primer for use over a wide range of substrate types

PRINCIPAL CHARACTERISTICS

– good adhesion to steel and galvanized steel

– good adhesion to non ferrous metals

– good adhesion to various plastics and wood

– good adhesion to cement based building materials

– good wetting properties

– excellent water resistance

– good chemical resistance

– can be overcoated with alkyd, epoxy and polyurethane

– good abrasion and impact resistance

COLOUR AND GLOSS

white, red-brown – eggshell

About 7406 - SIGMACOVER 211

Two component polyamide cured epoxy primer for use over a wide range of substrate types

- good adhesion to cement based building materials

- good chemical resistance

- can be overcoated with alkyd, epoxy and polyurethane

Reviews

There are no reviews yet.